Heyl & Patterson has been engineering bulk material handling solutions since 1887. In the early 1960s Heyl & Patterson shifted its focus to the exponential growth of the coal and iron industries. Heyl & Patterson identified the need for stacking equipment and started manufacturing stacker/reclaimers to aid in the effective management of coal and iron ore stockpiles.

Read MoreHeyl & Patterson Blog

Tags: bulk material handling equipment, coal handling, stacker/reclaimers

Rehabilitating Aging Bulk Material Handling Equipment

Posted by H&P Blog on Wed, Oct 23, 2019 @ 03:10 PM

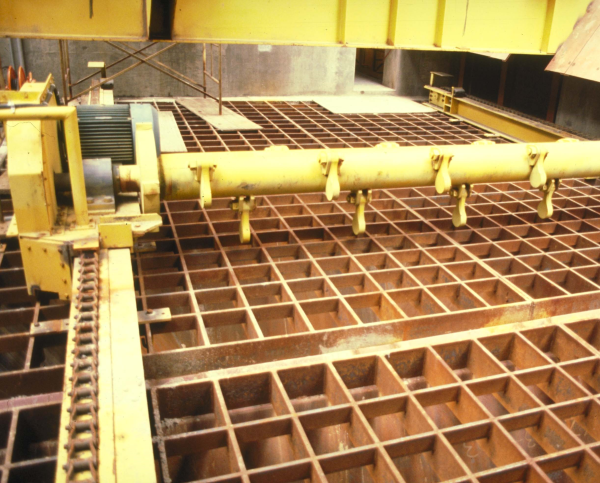

Bulk material handling equipment is an investment, it’s a large expense, and its useful life is often measured in decades. But what happens when that useful life comes to an end after 40 years of service, and there is no capex budget for a replacement? That's when H&P steps in to help you rehabilitate aging equipment for a longer future of material handling. H&P will help customers to progressively replace equipment components to return aging machinery back to its original specs.

Read More

Tags: bulk material handling equipment, power generation, upgrades

Chock Talk - Train Stabilization with Railcar Holding Devices

Posted by H&P Blog on Thu, Aug 25, 2016 @ 07:43 AM

Safety is undoubtedly the greatest concern for all rail facilities. A loading or unloading facility can quickly become a dangerous place when a railcar is not securely positioned. Soul Asylum said it best, “Runaway train never going back, wrong way on a one way track.” So how do you prevent a runaway train? With chocks!

Read MoreTags: railcar movers, railcar indexers, railcar dumpers, unloading, railcar holding

Improving Railcar Moving Efficiencies with The CUB Indexing System

Posted by H&P Blog on Thu, May 12, 2016 @ 03:47 PM

Railways keep the grain industry moving, quite literally. The majority of grain movement throughout North America is handled by truck, barge and rail logistics. Grain elevators, loading terminals and a variety of other facilities need to be able to index cars in order to get them loaded, unloaded and well on their way. Heyl & Patterson has perfected the art of railcar positioning in a simple and effective manner.

Read MoreTags: grain, railcar movers, railcar indexers, CUB railcar mover, train positioners

Benefits of a Variable Frequency Drive for Railcar Unloading

Posted by H&P Blog on Thu, Feb 04, 2016 @ 10:15 AM

The lifespan of a Heyl & Patterson Railcar Dumper can be measured in decades. It is not uncommon for unloading facilities to have equipment with a useful life that exceeds 30 years. To maintain the integrity of the equipment and prolong this lengthy lifespan upgrades are essential.

Read MoreIcy temperatures across the Midwest and Northeast pose a concern for those who can’t afford to let a little chill stop them in their tracks.

Read MoreTags: hammermill, railcar dumpers, unloading

Smarter, Stronger, Safer - Innovative Solutions for Unique Challenges

Posted by H&P Blog on Fri, Jan 15, 2016 @ 10:38 AM

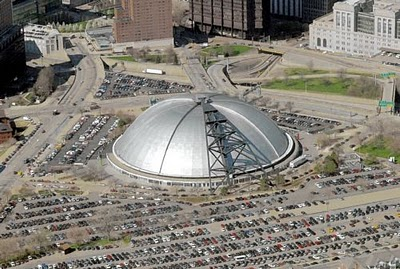

Many people think of Heyl & Patterson only as equipment manufacturers for the coal and steel industries, and they’re not wrong, however, our real passion is found in engineering solutions. Building custom equipment for thousands of customers across the globe is only one of H&P’s many pursuits, but our real knack is problem solving, which keeps us moving forward. In 129 years we have uncovered solutions for some very unique problems.

Read MoreTags: upgrades, aftermarket, field service

Happy New Year! As we head into a new year many of us resolve to be less stressed, more efficient and in the best shape of our lives. Those same resolutions can often be applied to capital equipment. So while you are setting those goals to improve your well-being in 2016, let us review the ways we can improve the life of our equipment. A few simple preventative maintenance items can make 2016 your continuous barge unloader’s best year yet.

Read MoreTags: barge unloaders, grain, maintenance, coal handling, continuous barge unloader (cbu), upgrades, inspections

Railcar Movers Keep Urea Processing Plants Pushing Forward

Posted by H&P Blog on Wed, Dec 16, 2015 @ 10:00 AM

Urea, sometimes called carbamide, is a solid organic crystalline compound that is colorless, odorless and highly water soluble. It is formed naturally in mammals, and serves an important role in the liver as the main nitrogen-containing product that breaks down amino acids, proteins and ammonia into waste. The kidneys scrub the urea from the blood and deposit it into the urinary tract, and it then makes up the chief solid material dissolved in urine. Urea can also be synthesized inexpensively from abundantly available inorganic materials. Because urea offers wide-ranging uses in many different industries, it is produced regularly and is available in large quantities for use throughout the world.

Read MoreTags: bulk material handling equipment, railcar movers, fertilizer, railcar indexers, CUB railcar mover, train positioners

Wood Pellet Exports Supply Europe's Inexhaustible Need

Posted by H&P Blog on Wed, Nov 18, 2015 @ 09:10 AM

The European Union plans to turn heavily towards using renewable energy in order to reduce emissions by 80 percent before 2050. They are focused on reaching this goal, not just through the use of solar and wind but also wood pellets. In numerous European countries, the use of wood pellets to produce electricity is becoming more commonplace. Pellets are a by-product made from the sawdust, bark, chips and other pieces of scrap wood that are generated by the processing of trees into lumber. The pieces are milled, dried and pressed into a pellet shape, and the lignin in the wood plasticizes to form a natural glue that allows a pellet to remain in one piece.

Read MoreTags: power generation, wagon tipplers, biomass, wood chips, railcar dumpers